Library

| Terminology | Tooth Geometry | Hook Angle | Formula | Cutting Speed | Basic information |

|---|---|---|---|---|---|

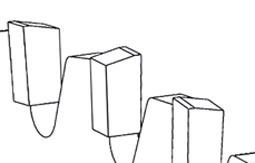

Main Tooth Geometry

|

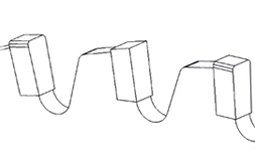

1. TC + FT Tooth |

| Combined the Triple Chip and Flat Top Tooth. Breaks up the chips and stabilizes the blade while cutting operation. Suitable for cutting ferrous solid bars, billets and non ferrous material. |

|

|

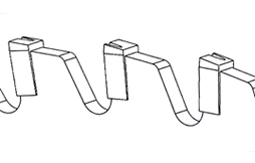

2. Flat Top Tooth with Notching |

| Flat Top Tooth geometry is the most effective in cutting. The notch on the OD breaks up the chips and its removal. Suitable for cutting thick walled metal tube / pipe and structual section. |

|

|

3. TC + FT corner breaks Tooth |

| Combined the Triple Chip and Flat Top corner break Tooth. Breaks up the chips and stabilizes the blade while cutting operation. Flat Top corner break tooth for strengthen the outside cutting edge of carbide to prevent breakage. Suitable for cutting medium carbon steel plate & stainless steel plate. |

|

|

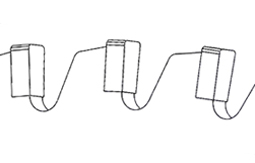

4. ATB Tooth |

| Alternate Top Bevel Tooth geometry provides high shear cutting. Effective where close tolerances are required. Suitable for cutting thin walled non-ferrous profiles & tubes. |

|

|

5. ATB Tooth with corner break |

| Modified the corner of Alternate Top Bevel Tooth geometry reduces the weakness of sharp carbide edge. Suitable for cutting thin walled non-ferrous profiles & tubes. |

|

|

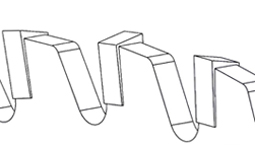

6. TC + Transform ATB Tooth |

| Special 3 tooth tooth geometry reduces the cutting pressures and stabilizes the blade in cutting operation. Obtain smooth surface finish. Suitable for cutting non-ferrous metal plate where better finish required. |

|